- +1-563-340-2569

- admin@circledatasystems.com

- Sales: Mon - Fri: 9:00 - 17:00 / Support 24/7

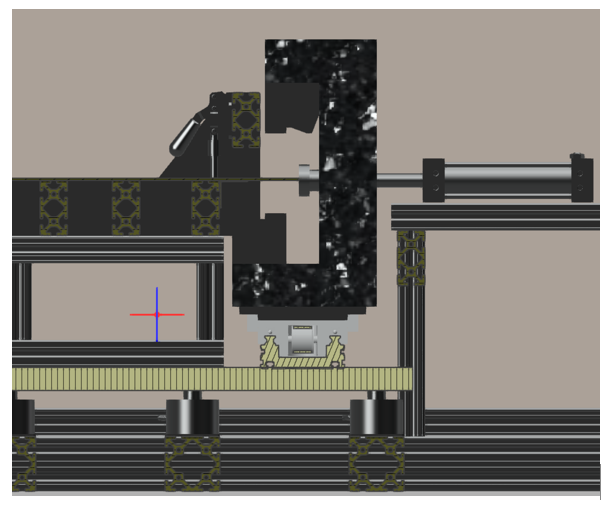

1. Uses high precision laser, width 0.05 micro repeatability. It is measure by two laser that make immune to position and vibration.

2. Measurement is vibration isolated with air cushions.

3. Calculate Strip Crown and Strip Wedge.

4. Signal processing, many ways to filtering the data is available and the best to your type pf data will be implemented.

5. All aluminum Structure.

6. Ability to save all data to SQL data base or in no-SQL formats.

7. Width adapted to your mill.

8. The Spray pattern can be display on top of the measurement.

9. All operation is automatic after clamp the sample.

10. The system is all protected by acrylic panels, easy to open for maintenance.

11. 10 inches Touchscreen monitor convenient located.

12. Pneumatic or electrical retract positioners on the back.

13. Manual Clampers for safety.

14. Z-axis control by step motor.

Min Thickness: 2 mm (0.08”)

Max Width: 2500 mm (100”)

Sensor dual reflective laser: 0.05 repetibility.

Approximated Time for reading: 1 - 2 minutes.

Measurement Gap: 50 mm

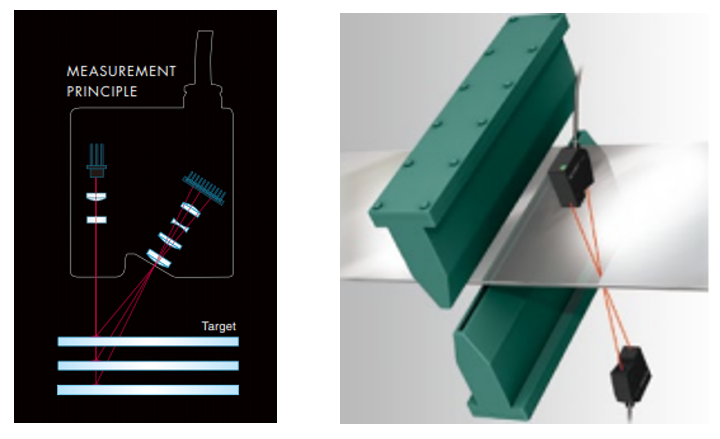

Measurement Principle: Circle Profile Gauge uses two laser sensors against each other to eliminate interference from shape or position.

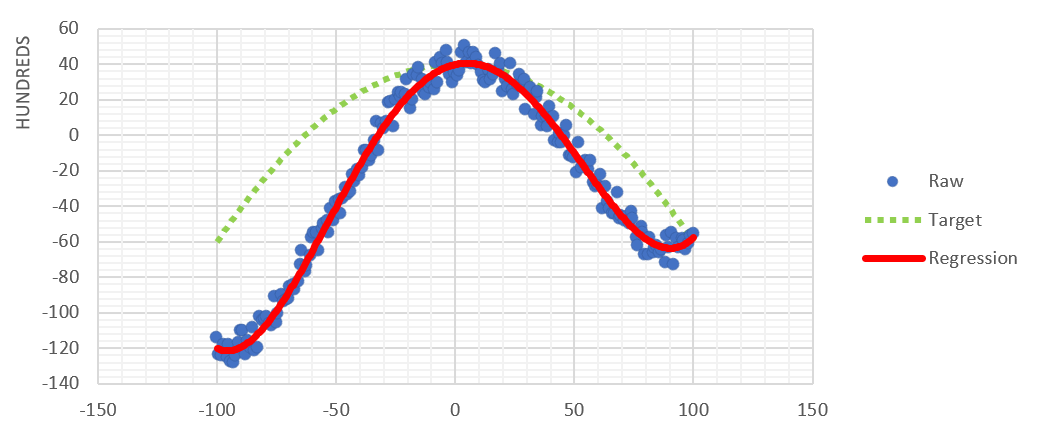

Profile Measurement Chart: It show in blue the measurement data and the red line is the regression made from the data. The green dot-line represents the target for profile and an error line can be added.

The lasers are assembled in a low deflection C frame to minimize interference from Temperature variation and vibration. Retractable positioner is used to the initial setup of the sample.